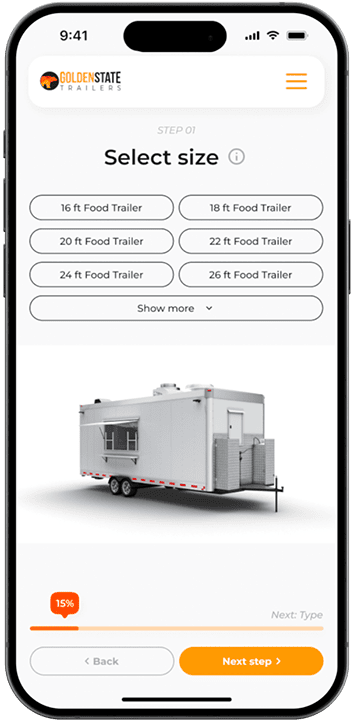

Galley Flow Mapping is the structured analysis and planning of a food trailer’s interior kitchen layout to streamline staff movement, equipment placement, and task sequencing. In the confined environment of a mobile food unit, effective galley flow design minimizes congestion, enhances safety, and supports consistent food quality. This process is critical during initial trailer buildouts or redesigns, ensuring compliance with health regulations while maximizing operational efficiency.

Before finalizing your trailer’s interior, map out the full production process from inventory storage to customer delivery. Identify choke points, redundant steps, or safety risks. Collaborate with staff or a trailer layout specialist to model different configurations and test for flow. A well-executed galley flow plan enhances speed, safety, and overall service quality.

Service Hatch Limit

The Service Hatch Limit defines the maximum safe angle or extension range at which a food trailer’s service hatch can be operated without compromising safety or structural integrity. This specification is critical to prevent damage to the hatch assembly, avoid injuries from sudden closures or overextension, and ensure consistent functionality during vendor operations. The service […]

Service Hatch Limit

The Service Hatch Limit defines the maximum safe angle or extension range at which a food trailer’s service hatch can be operated without compromising safety or structural integrity. This specification is critical to prevent damage to the hatch assembly, avoid injuries from sudden closures or overextension, and ensure consistent functionality during vendor operations. The service […] Breakaway Cable Check

The term Breakaway Cable Check refers to the procedure of verifying that a food trailer’s emergency breakaway cable is securely connected to the tow vehicle and is functioning correctly before transport. This safety mechanism is designed to engage the trailer’s brakes automatically if it becomes unhitched while in motion. For mobile food operations, performing this […]

Breakaway Cable Check

The term Breakaway Cable Check refers to the procedure of verifying that a food trailer’s emergency breakaway cable is securely connected to the tow vehicle and is functioning correctly before transport. This safety mechanism is designed to engage the trailer’s brakes automatically if it becomes unhitched while in motion. For mobile food operations, performing this […] Trailer Ground Strap

A Trailer Ground Strap is a conductive component that connects the metal frame of a food trailer to an established grounding point, allowing electrical current or static charges to safely dissipate into the earth. In mobile food operations, this strap plays a critical role in maintaining electrical safety when connecting to external power sources or […]

Trailer Ground Strap

A Trailer Ground Strap is a conductive component that connects the metal frame of a food trailer to an established grounding point, allowing electrical current or static charges to safely dissipate into the earth. In mobile food operations, this strap plays a critical role in maintaining electrical safety when connecting to external power sources or […]