Yes. Our hot dog and sausage food trailers are designed with health and sanitation requirements in mind. Layouts, materials and equipment selection support smooth health department inspections from the first review.

Yes. We assist customers in working with local jurisdictions and health departments. Trailer plans are prepared upfront so they can be reviewed early by inspectors and permitting offices.

Yes. Our trailers are designed using nationally recognized codes and standards. This includes applicable portions of IMC, UPC, IBC, ANSI, NFPA, IFC and IFGC, depending on the jurisdiction.

Yes. We install commercial-grade equipment that meets recognized standards such as NSF and ETL. This supports food safety, sanitation and inspection approval.

Yes. Each trailer is custom planned based on your menu, service volume, and workflow. We account for prep space, cooking equipment, storage and service window placement.

Yes. Every project begins with detailed trailer plans. This allows customers and local authorities to review layouts, systems, and equipment before production begins.

Yes. We have direct experience working with California HCD and Washington L&I. Our team coordinates plan reviews and approvals to obtain the required insignia certifications.

Yes. When required, we design and integrate certified commercial fire suppression systems. Designs follow applicable NFPA requirements and allow proper inspection and maintenance access.

Our trailers use heavy-duty frame construction built 12 inches on center with 1-1/8″ laminated hardwood flooring. The underside is protected to help resist moisture and environmental exposure.

Yes. Each customer is assigned a dedicated project manager. You receive clear communication, production updates, and photo progress throughout the build.

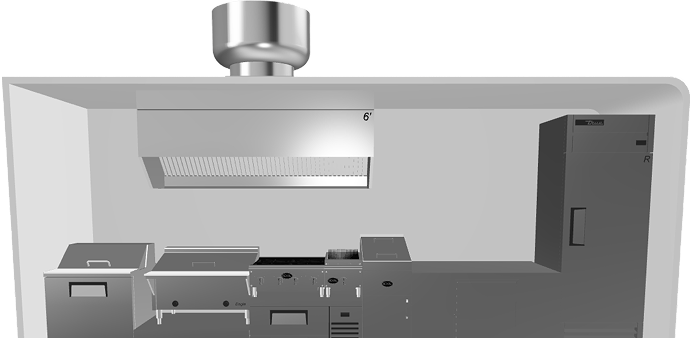

Building a hot dog trailer starts with planning, not construction. The menu defines equipment, layout, power load and ventilation needs. A custom hot dog trailer or mobile hot dog trailer is built around grills, steamers and dedicated prep space. Sausage service adds grease management, ventilation and fire safety requirements.

Many first-time owners focus on price instead of layout. This often leads to inspection issues and costly redesigns. A proper build starts with detailed trailer plans. Plans allow early review by health departments and local jurisdictions.

Code-aware construction matters from the beginning. Electrical, plumbing, ventilation and fire suppression systems must work together. When systems are planned upfront, approvals move faster. This helps the trailer pass inspections on the first review. To understand costs early, many owners request a hot dog trailer quote after defining their layout and equipment needs.

Many hot dog trailers fail inspections due to poor planning. The most common issue is layout that ignores workflow and sanitation zones. Ventilation is another frequent problem.

Grills and sausage equipment create grease and heat that require proper exhaust. Fire suppression is often overlooked.

Missing or incorrect systems delay approvals and increase rebuild costs. Permits and local requirements vary by state and city. Trailers built without jurisdiction review often need changes after delivery. Electrical and plumbing loads are miscalculated in many DIY builds. This causes power issues and failed inspections.

Another risk is buying a “cheap” hot dog trailer for sale. Low upfront cost often means non-compliant equipment and layouts. These problems slow down opening timelines. They also increase total project cost after the trailer is built.

Health inspections are a major challenge when learning how to build a hot dog trailer. Many owners face delays because layouts and systems are not planned to code from the start. Custom-built hot dog food trailers and sausage food trailers are designed with inspections in mind. The process starts with detailed trailer plans prepared before construction. These plans can be reviewed by local health departments early, reducing the risk of changes after the build begins.

Proper workflow is critical. Cooking, prep, storage and handwashing areas must be clearly separated. NSF-certified equipment, stainless steel surfaces, and approved sink setups help meet sanitation requirements during inspections.Code compliance also matters. Custom hot dog trailers are designed using nationally recognized standards, including applicable portions of IMC, UPC, IBC, ANSI, NFPA, IFC, and IFGC, depending on the jurisdiction.

Fire safety systems are integrated when required. Ventilation, gas connections, and fire suppression layouts are planned for inspection access and long-term maintenance. This approach helps hot dog trailers pass health inspections on the first try. It avoids rebuilds, reduces delays, and allows operators to open faster with fewer surprises.

Proper hot dog trailer planning starts with aligning layout, equipment and compliance requirements. Your menu defines everything that follows. Hot dog and sausage concepts require clear cooking and prep zones. Grills, steam tables, refrigeration and sinks must work as one system.

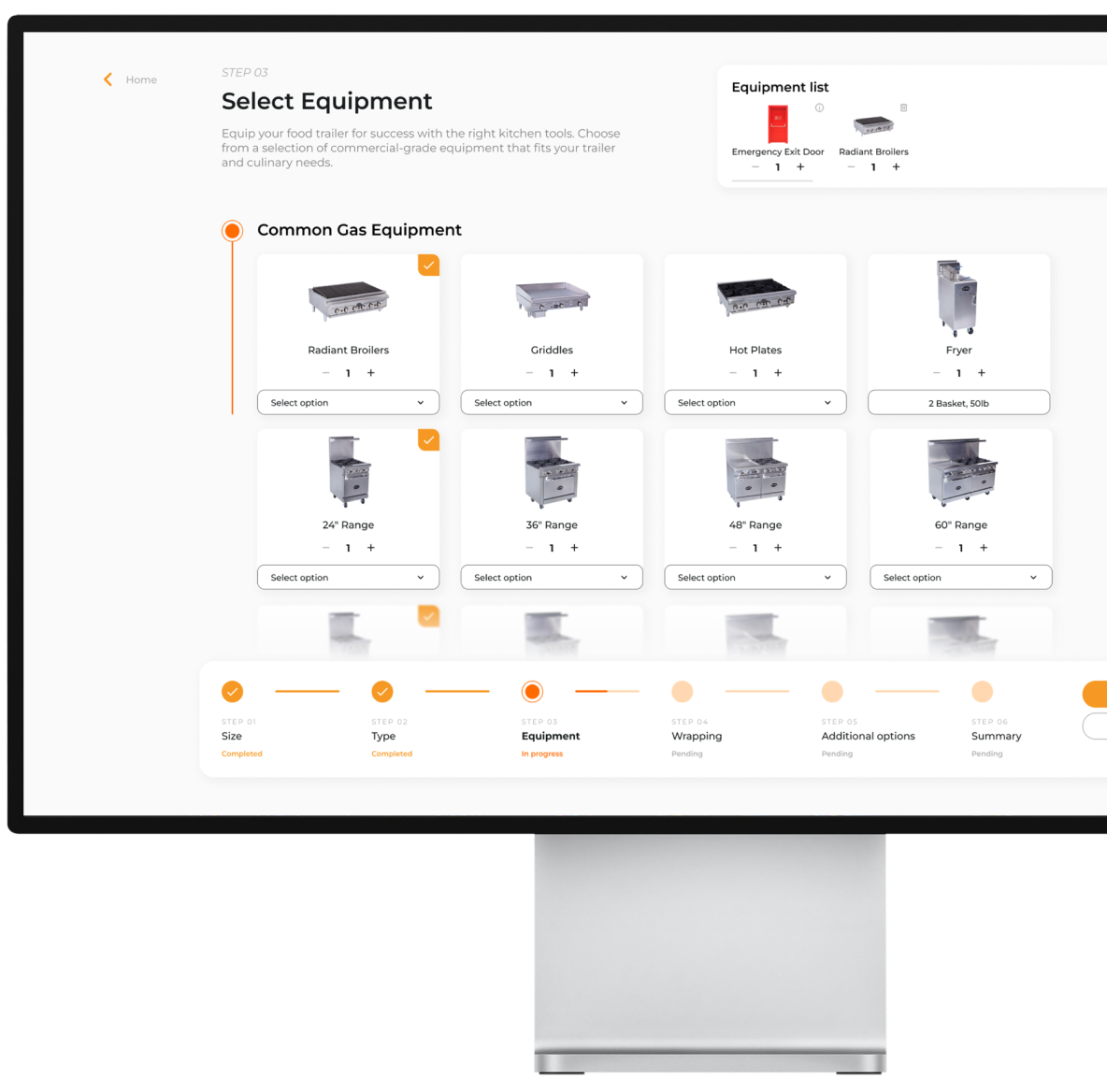

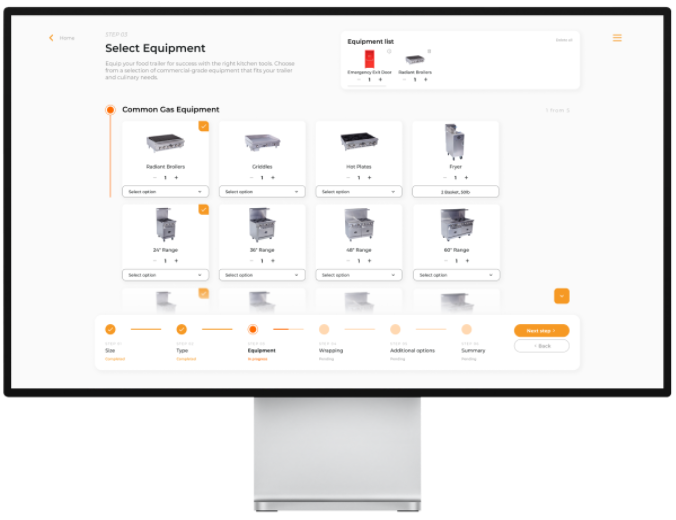

This is why custom planning matters when learning how to build a hot dog trailer. Generic layouts rarely match real service conditions or local requirements. Using a planning tool helps avoid common issues. The free food trailer configurator allows you to define trailer size, equipment and layout before production begins. This makes it easier to align workflow, utilities and inspection needs. A properly planned hot dog food trailer is faster to approve and easier to operate. It also protects your budget and launch timeline.

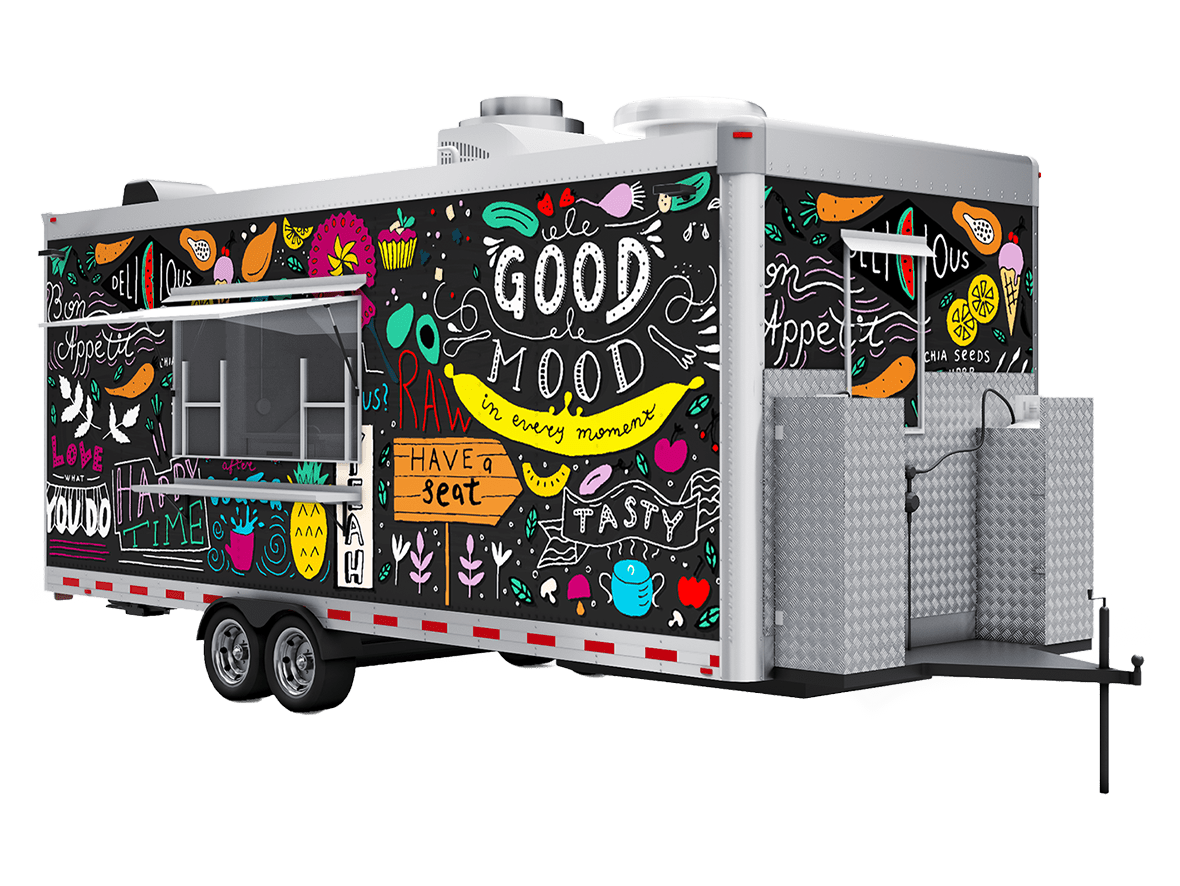

Searching for a hot dog concession trailer or hot dog trailer for sale often leads to price confusion. Many listings show base prices that do not include real equipment or compliance needs. The final cost of a hot dog food trailer depends on several factors. Trailer size, cooking equipment, refrigeration, fire safety systems and local code requirements all affect pricing. Location also matters. Permits and inspection rules vary by state and city, which changes build specifications.

This is why generic pricing rarely works for hot dog trailers for sale near me searches. Without reviewing your menu and service format, quotes are often inaccurate. A proper quote starts with project details. Menu, expected volume, staffing and jurisdiction requirements define the build.

Requesting a custom quote helps avoid hidden costs later. It ensures the trailer is planned, built and priced for real operation, not assumptions. You can request a quote for a custom hot dog trailer to get a configuration that matches your business goals and local requirements.

Building a hot dog trailer is not only about equipment. It is about approvals, inspections, and long-term operation. Golden State Trailers follows a plan-first approach.

Every project starts with detailed trailer plans before construction begins. This allows early review with health departments and local jurisdictions. We assist customers with permits and approvals. This support helps avoid delays caused by local requirements that are often missed.

Our trailers are built using NSF-certified commercial equipment and food-safe materials. Layouts are designed with sanitation, workflow and inspection logic in mind. Code awareness is built into every project. Trailers are designed using nationally recognized standards, adjusted for each jurisdiction.

Fire suppression and ventilation systems are integrated when required. They are planned for inspection access and long-term maintenance. Each customer works with a dedicated project manager. You receive clear communication, production updates and photo progress during the build.

All trailers are built in the USA with heavy-duty frame construction. Floors and undersides are protected for durability and daily commercial use. Before production begins, you can plan your layout using the food trailer configurator online to define size, equipment and workflow. When you are ready to move forward, you can request a custom hot dog trailer quote based on your menu and local requirements.